MAMAC tailor produces sample items for fashion shows and collections. Customers have different needs and Mamac’s dressmakers have the ability to face every request.

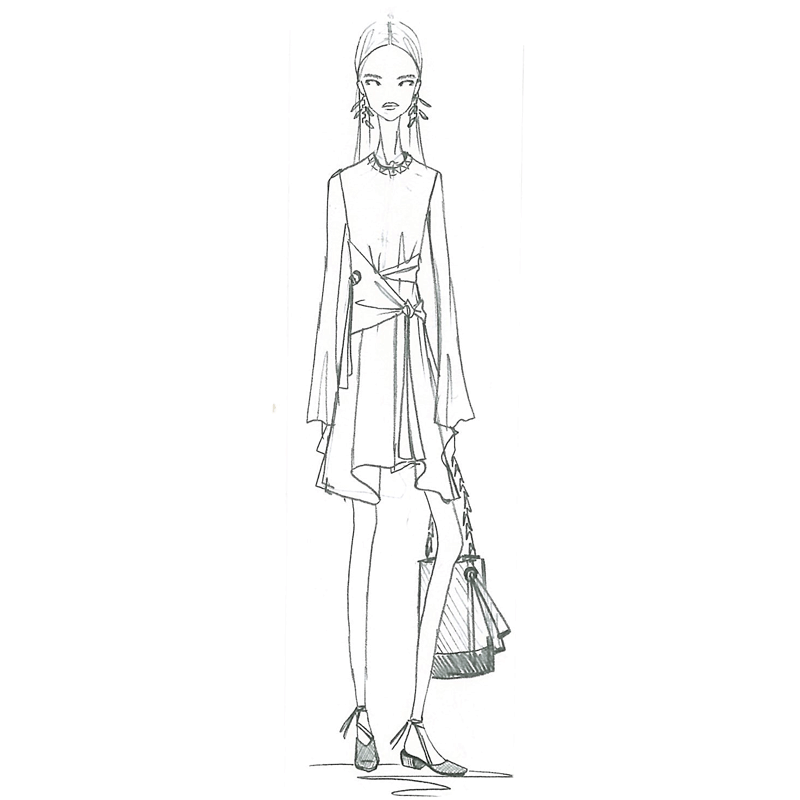

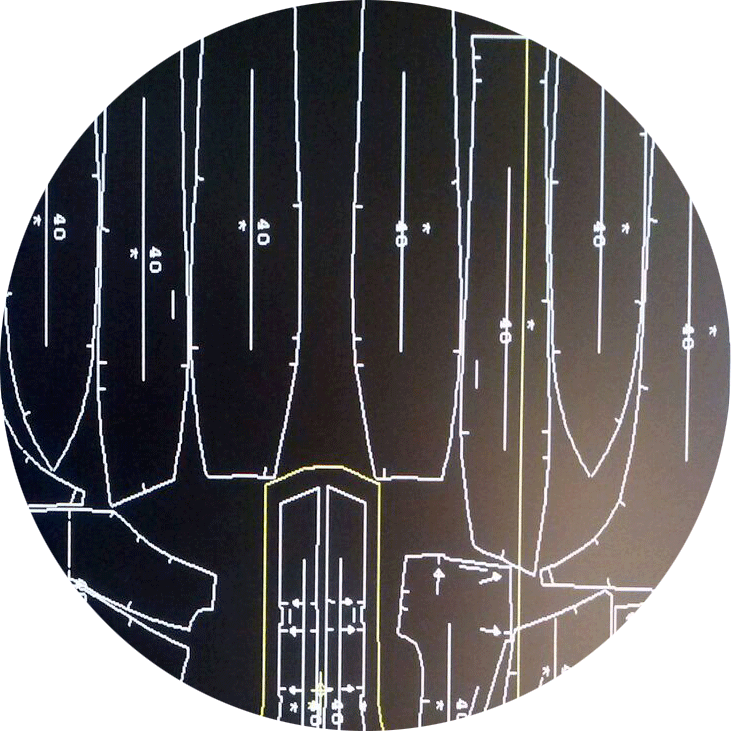

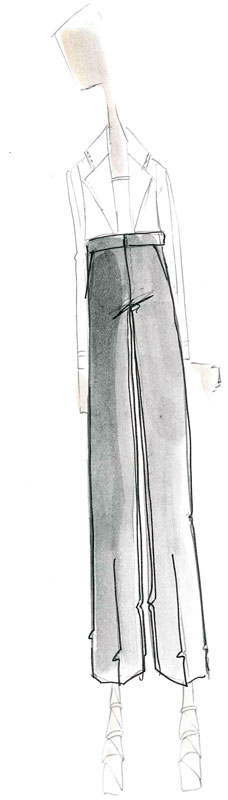

Using a sketch or a couture piece as a starting point, our dressmakers prepare the sewing pattern in the CAD room and arrange the fitting with a model, in order to realize the production of the garment in various sizes.

When the fitting ends, the garment’s production is ready to start; after that, it’s time for ironing, labeling and packaging.

The final step is the delivery to the client; Mamac deals directly with the chosen courier and take care of all the paperwork for the customs. All the aforementioned steps are managed in-house by the company with no third parties involved.